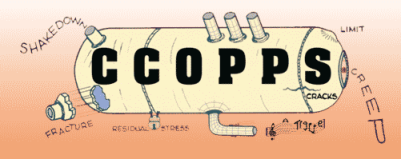

The CCOPPS Industry Needs Survey highlighted facilities for weld modelling and assessment as poor by 53% of respondents. Given also the prevalence of welding in pressure vessels and the role of fatigue as a major failure mechanism, the topic of this second CCOPPS webinar, delivered by a renowned expert in the fatigue of welded components, should be of wide interest.

After a brief introduction to the main features of welded joints that affect their fatigue performance, various design methods, and associated fatigue resistance data in the form of S-N curves, for the avoidance of fatigue failure are described. Specific examples of fatigue design rules for pressure vessels, including those in EN 13445, BS PD 5500 and ASME VIII, are then presented and compared. Topics to be addressed include the stresses used, with special attention to the structural hot-spot stress, including methods for its determination and fatigue test data that provide a basis for corresponding design S-N curves, plasticity corrections and the treatment of multi-axial loading. In addition, required corrections to S-N curves, fatigue life improvement methods, assessment of welding imperfections and design on the basis of special fatigue test data are covered. Finally, screening tests, to avoid the need for further consideration of fatigue, and simplified fatigue design methods, are compared.

Agenda

Introduction and CCOPPS Update

Dr. Jim Wood, University of Strathclyde and CCOPPS Project Co-ordinator

Fatigue of Welded Pressure Vessels

Professor Stephen Maddox, TWI

Q & A Session

Closing

1 This webinar is the second in a series of four sponsored by the CCOPPS project, which is funded by the EU under the Leonardo initiative. The project is focussed on the development of the competence of users of FEA in the power and pressure systems industry. The project partners are the University of Strathclyde, University of Malta, University of Stuttgart, Technical University of Warsaw, CETIM and NAFEMS.

Back to All Webinars

Professor Stephen Maddox is Fatigue Technology Manager at TWI in Cambridge UK, where he has almost 40 years experience in the design and engineering performance of welded components and structures, with emphasis on fatigue. Apart from research and consultancy, he has been involved extensively in the development of design recommendations and procedures, notably for bridges, pressure vessels, offshore and aluminium structures, and the practical application of fracture mechanics to fatigue. In his current position he acts as specialist advisor to other staff, technical supervisor of major projects and TWI representative on a number National and International code-writing committees. He is currently Visiting Professor in the Department of Mechanical Engineering at the University of Strathclyde.

Professor Stephen Maddox is Fatigue Technology Manager at TWI in Cambridge UK, where he has almost 40 years experience in the design and engineering performance of welded components and structures, with emphasis on fatigue. Apart from research and consultancy, he has been involved extensively in the development of design recommendations and procedures, notably for bridges, pressure vessels, offshore and aluminium structures, and the practical application of fracture mechanics to fatigue. In his current position he acts as specialist advisor to other staff, technical supervisor of major projects and TWI representative on a number National and International code-writing committees. He is currently Visiting Professor in the Department of Mechanical Engineering at the University of Strathclyde.  Dr. Jim Wood, leader of the CCOPPS project, is a senior member of staff in the Department of Mechanical Engineering at the University of Strathclyde. In addition to wide research interests, he has provided consultancy in the PV area for some 30 years and also taught FEA for 10 years on an MSc in PV Design. Particular interests include finite element analysis of pressure vessels and the modelling and fatigue assessment of welded components. He has been a member of NAFEMS since its formation and is currently a member of Council, as well as member of the ETWG, assessor for the Registered Analyst Scheme and on the organizing Committee for the

Dr. Jim Wood, leader of the CCOPPS project, is a senior member of staff in the Department of Mechanical Engineering at the University of Strathclyde. In addition to wide research interests, he has provided consultancy in the PV area for some 30 years and also taught FEA for 10 years on an MSc in PV Design. Particular interests include finite element analysis of pressure vessels and the modelling and fatigue assessment of welded components. He has been a member of NAFEMS since its formation and is currently a member of Council, as well as member of the ETWG, assessor for the Registered Analyst Scheme and on the organizing Committee for the