Procedural Benchmarks For Common Fabrication Detail

A summary report of the FENet Education and Dissemination (E&D)

workshop in Majorca, Spain, 25th March 2004.

By Dr. Jim Wood, University of Strathclyde, UK

By Dr. Jim Wood, University of Strathclyde, UK

This article provides a summary of the observations made at the

Education and Dissemination session in Majorca, which was

reasonably well attended and resulted in 3-4 hours of stimulating

discussion.

The three procedural benchmarks are shown below.

Results obtained from all contributors are available for download

for each benchmark, as well as results and the benchmarks

themselves. The following observations are based on the results

contained in these spreadsheets and also from the more

comprehensive submissions made by participants.

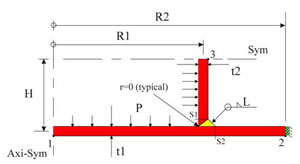

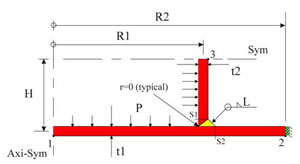

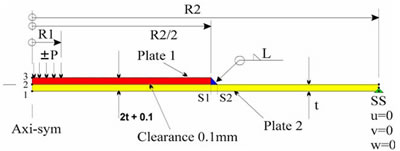

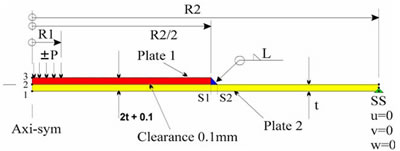

Fig. 1 Procedural Benchmark FENET_E&D1 “Shell

Intersection”

Benchmark Download (PDF)

Results Download (PDF)

Local Stresses

Stiffness, Overall, Field

Presentation Download (PDF)

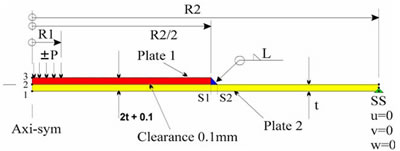

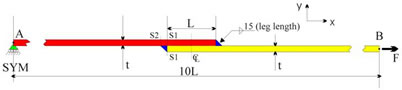

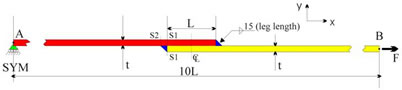

Fig 2 Procedural Benchmark FENET_E&D2 “Shell

Reinforcement”

Benchmark Download (PDF)

Results Download (PDF)

Local Stresses

Field Stresses

Stiffness & Overall Stresses

Presentation Download (PDF)

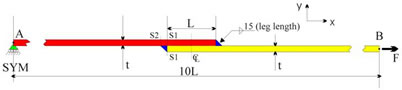

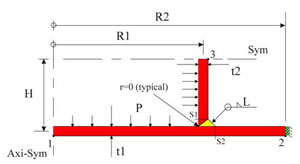

Fig. 3 Procedural Benchmark FENET_E&D3 “Offset Shell

Mid-surface”

Benchmark Download (PDF)

Results Download (PDF)

Local Stresses

Stiffness, Overall & Field Stresses

Presentation Download (PDF)

Generic observations

1.

Significant variation in the modelling, results, assessment and

conclusions relating to fitness for purpose of such detail is

apparent across analysts and industry sectors, for both static and

fatigue situations.

2.

Human error is apparent, including:

a. Mis-interpretation of boundary conditions;

b. Incorrect use of finite element functionality that altered

physical response;

c. Reporting wrong results;

d. Using stress output directly at singularities;

e. Using averaged stresses at shell intersections.

3.

Lack of “engineering common sense” is apparent. For

example, not all contributors checked that the field stresses

compared well with hand calculations, where appropriate.

4.

From this limited linear elastic exercise:

a. The need for finite element knowledge is confirmed;

b. The need for general engineering education is confirmed;

c. The need for industry specific knowledge is confirmed;

d. The need for validation is confirmed;

e. The need for adequate QA procedures is also confirmed.

5.

Established “common best practice” across the various

industry sectors is not apparent.

6.

Various guidelines exist for weld modelling and assessment in few

industry sectors.

7.

Use of experimentally derived results on real weld geometries is

recognised as a necessary part of the assessment process for

fatigue. It is how FEA results are obtained (often at locations

where singularities exist) that provides variations in approach.

8.

As with all analyses, the adequacy of any idealisation must be

judged in terms of the purpose of the analysis being conducted. The

idealisation of such fabrication detail will affect static and

fatigue (and dynamic, buckling, limit and fracture assessments) to

different degrees.

9.

The influence of fabrication detail can be local or global in

nature and this fact should be considered when judging adequacy.

The details selected for consideration as “procedural

benchmarks” have both local and global measures selected as

targets and all showed variation.

10.

It is possible to use shell models to obtain necessary stress data

for fatigue assessment of such details, but care and understanding

is necessary. It should also be recognised that shell models will

produce finite converged results at intersections.

11.

There would appear to be two distinct approaches to obtaining

“hot-spot” stresses from finite element models:

a.

A stress linearization procedure (not required with shell

representations), designed to remove the peak stress component and

leave the membrane and bending stress components. Such an approach

will include gross geometric stress concentration effects. Some

finite element systems provide post-processing tools for defining

the “assessment section” in both 2D and 3D

representations and for linearising the results. This approach is

common in the Pressure Vessel industry.

b.

A number of “extrapolation” approaches, with

slight variations in the extrapolation procedures, are in use.

These approaches invariably involve element sizes of the order of

0.4t and differ in whether linear or quadratic extrapolation is

used to the hot-spot location (which is often a singularity in

nonshell models). Some of these procedures also provide details of

how the stress distributions from shell models should be displaced

by up to half a shell thickness (depending on the angle of the

intersection), before extrapolating to the hot-spot. However, it is

recognised that specific Codes of Practice may not give the analyst

any choice in which procedure to adopt.

12.

Some fatigue assessment procedures require the use of the stress

range on the weld throat area. Stresses plotted across the throat

will show a highly non-linear variation. Although not always clear,

it is likely that an average value of stress is required from the

results, to provide consistency with hand calculations. Although

not always clear, it is likely that a simple ‘membrane +

bending’ value of stress, with peak component removed, is

required from the results, to provide consistency with hand

calculations.

13.

Some analysts used thick shell elements. The fact that most did

not, would perhaps indicate that participants from different

disciplines do not have a common understanding of when plates and

shells become thick.

14.

Given the nature of the Displacement Finite Element Method and the

details examined, it is perhaps not surprising that greatest

agreement is apparent for global stiffness ( as measured by overall

displacements), closely followed by field stresses (by definition

away from local stress concentrations). Greatest variation is

apparent for local stresses, which include finite values derived

from distributions in the vicinity of singularities. In addition,

as would be expected, greatest variation is apparent for very small

target values, with best agreement generally for large values.

Preliminary observations for E&D1

1. For this detail, the practice of displacing shell stress

distributions by half a shell wall thickness before interpolating

values at the “notional” position of weld toes

(hot-spot), would seem unnecessary.

1. For this detail, the practice of displacing shell stress

distributions by half a shell wall thickness before interpolating

values at the “notional” position of weld toes

(hot-spot), would seem unnecessary.

2. The various results provided by “Analyst Identifier

1” show remarkably little variation amongst 2D-Axi and shell

models (with and without weld representation). Whilst inclusion of

the weld stiffness (by whatever means) improves the comparison with

the highly refined 2D-Axi results, it is not apparent that this

additional complexity is merited over a simple shell representation

and use of stresses at the location corresponding to the weld toe.

3. Although not considered in these benchmarks, it is noted that a

simple shell intersection representation already has too much mass,

without the addition of any measures designed to include the effect

of the weld. This will have some bearing on dynamic analyses and

weld models will result in a greater need to reduce the density of

local elements for accurate representation.

Preliminary observations for E&D2

1. The reason for the large variation in contact radius results for

load case 2 is not apparent. This is clearly a function of global

stiffness representation as well as the effectiveness of the

contact methods used. Given the relatively good agreement on

overall deflections in most cases, it must be assumed that the

differences are largely due to the contact methods. This fact

emphasises the need for adequate contact benchmarks.

1. The reason for the large variation in contact radius results for

load case 2 is not apparent. This is clearly a function of global

stiffness representation as well as the effectiveness of the

contact methods used. Given the relatively good agreement on

overall deflections in most cases, it must be assumed that the

differences are largely due to the contact methods. This fact

emphasises the need for adequate contact benchmarks.

2. The various results provided by “Analyst Identifier

1” show remarkably little variation amongst D-Axi and shell

models for deflections, field stresses and weld-toe stresses, for

load case 1. The poor comparisons for load case 2 are due to the

lack of contact simulation in the shell model for load case 2.

3. Assuming the reinforcing plate to be integral did not provide

good agreement for field stresses at the plate centre. The

comparison of local stresses in the region of the weld are

reasonable, particularly for those of larger magnitude. It is clear

therefore, that if such an assumption is to be made, then care must

be taken to ensure that both plates effectively act as one through

use of a suitable number of spot or puddle welds. The results

for the “central spot-weld” idealisation, would

indicate that an “integral” behaviour may be possible

with relatively few plate connections.

4. Neglecting the offset due to the reinforcing plate and assuming

a double thickness integral representation over the reinforced area

produced similar results to the “integral” idealisation

with offset.

Preliminary observations for E&D3

1. Only two participants showed that the problem was large

displacement (subsequently confirmed by the coordinator), in spite

of the tip deflection being less than the thickness of the plate.

1. Only two participants showed that the problem was large

displacement (subsequently confirmed by the coordinator), in spite

of the tip deflection being less than the thickness of the plate.

Reductions in deflections and stresses are significant. The rules

of thumb commonly used as a guide to when large displacement

effects become significant for beams, plates and shells are clearly

not applicable for this problem. The reason for this is apparent

when the source of the non-linearity is given due consideration.

2. 3D models (shells and bricks) show variations in results across

the width, which are obviously absent from 2D results. Not all

contributors commented on this effect.

3. Neglecting the offset, even with correct plate thicknesses,

fails to predict adequate values for overall stiffness, field

stresses and local stresses. Analysts should therefore think

carefully before neglecting offsets in plate/shell mid-surfaces, as

their effects can have a global nature as well as local. For

thinner plates/shells, large displacement effects may act to reduce

the global effect of the offset, through local bending of the joint

and effective realignment of the midsurfaces.

4. The modelling of contact between the lapped plates appears

irrelevant for the relative joint sizes considered. The results for

separate plates, with and without contact, and models where the

plates were assumed integral appear similar. The latter model

however, fails to pick up the stress singularity that exists at

either end of the lap running between fillet weld roots. Almost all

contributors failed to highlight this singularity, in any model.

Closure

The general consensus of those participating was that this was a

worthwhile exercise, that should be of interest to the wider FE

community. Given the level of participation, this fact was clearly

not always recognised. It should be recognised that the relevance

of the general observations clearly have broad interest to the

entire finite element community, it should also be recognised that

the relevance of the detail of the modelling strategies used is not

confined to those involved in welding 15mm thick steel plate! It is

now my task to try and pull together some sort of conclusions from

this exercise. To this end, I have asked contributors to have a

look at the final collated results and take the opportunity to

comment on the results that they provided in relation to the rest.

In addition, they have also been asked to have a look at the

preliminary observations and to comment on these and add their own

if necessary.

On receipt of everyone’s comments, I will then document the

exercise. The final document is likely to consist of several

parts…. An Introduction providing the background and aims of

the project; the Procedural Benchmark Specifications; the

“Round- Robin” results (with anonymity maintained);

observations from the exercise and finally some conclusions

regarding good and bad practice in the analysis and assessment of

such details.

This final report is now available to download, as well as being

available from NAFEMS in hard-copy format.

The download is available in a

lo-res PDF format (1.8MB),

as well as a hi-res format, in a zipped package (22MB).

By Dr. Jim Wood, University of Strathclyde, UK

By Dr. Jim Wood, University of Strathclyde, UK