Fatigue design of Additive Layer Manufacturing materials: defect size map

Yves Nadot and Carole Nadot-Martin, Institut Pprime, ISAE-ENSMA, Université de Poitiers

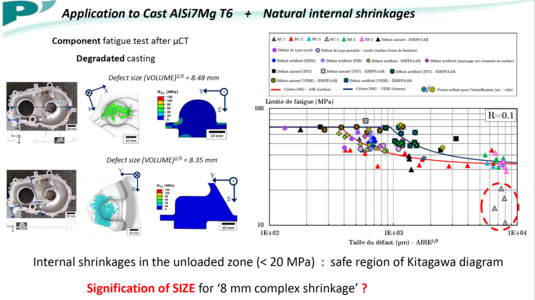

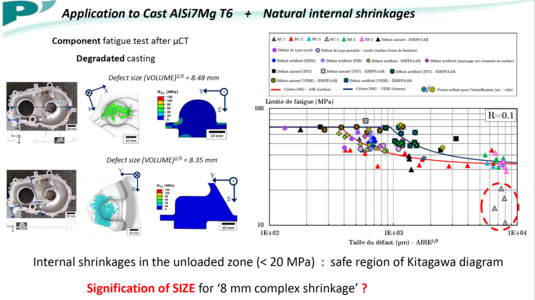

A modelling strategy is proposed to evaluate the influence of defect morphology on the fatigue limit of additively manufactured Al alloys by: (a, b, c) obtaining a 3D image of defect population from X-ray micro-computed tomography (μ-CT) or process simulation, (d) computing the Equivalent Inertia Ellipse of each individual pore, (e) modelling the influence of the defect on the fatigue limit through the DSG approach and, (f) 3D mapping the criticality of each individual defect. The Methodology is validated through fatigue tests conducted on AlSi10Mg alloy manufactured by selective laser melting.

Yves Nadot is a Full Professor at the National School of Mechanics and Aerotechnics, located at Poitiers Futuroscope. He leads the research teams “Damage” and “Physics and Mechanics of Materials” and is an active contributor to the research on the defect induced fatigue process. He worked on industrial collaboration projects with the companies SAFRAN, Zodiac Aerospace, Renault, Airbus, Knorr-Bremse, SNCF, and RR.