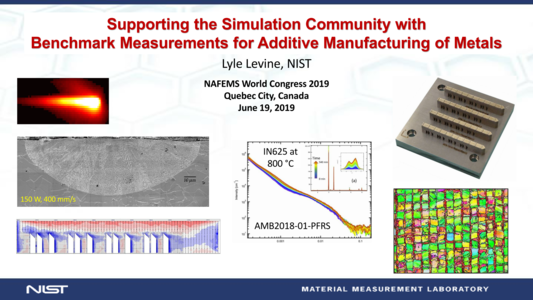

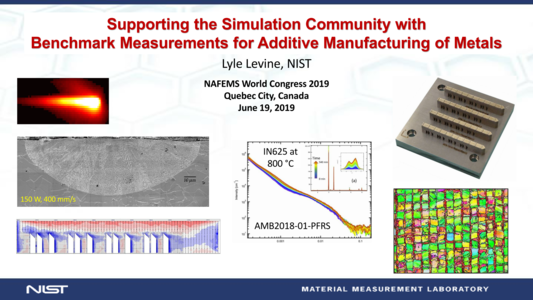

This presentation was made at the 2019 NAFEMS World Congress in Quebec Canada

Resource Abstract

Additive manufacturing (AM) of metal components is a rapidly growing advanced manufacturing paradigm that promises unparalleled flexibility in the production of parts with complex geometries. However, the extreme processing conditions createposition-dependent microstructures, residual stresses, and properties that complicatecomponent and process certification. Quantitative modeling of these characteristics is critical, but model validation requires rigorous measurements including comprehensive insitu monitoring of the melt pool behavior, along with microstructure, residual stress, and property characterizations. To be useful, such benchmark measurements must be accepted broadly by the international AM community so that meaningful comparisons can be made. I will describe our establishment of the Additive Manufacturing Benchmark Test Series (AM-Bench), a continuing series of highly controlled benchmark tests for additive manufacturing that modelers around the world are now using to test their AM simulations.